What are the design models in Design Management is the twelfth article of a series. Articles about design management in architecture practice. I have discussed in the previous articles what is design management, who is the design manager in practice. Also, firm or project design management plan, what are the key functions of a design management plan in practice? In addition, what needs to be managed in architecture firm. And this article is the seventh article on building and writing a design management plan.

Design models, in the design management plan, represent the models used to assure the quality of production of a project at hand. Firms use these models to gauge and measure the quality of service. The professional bodies in the world, in Europe, focus on quality assurance. They produce circulars, video training, and programs to develop their firm’s staff. In the following article, we will stand on the difference between architecture and product quality assurance. I have discussed the quality management system and built an indicator in my previous article.

The design management plan includes the design models used by the firm in the daily work of the architectural design process. Also, combined with the review and checking of production by the quality management system. The two models are used, and some firms in the world bind their work design models to the RIBA plan.

In practice, firms use the two models, the traditional model and the sequential model, but they are not really connected to the RIBA plan. Riba’s plan illustrates the phases of the design and construction of an architectural project. The plan, you can download here, includes a mix of design brief work, HSE requirements, construction, and procurement. In addition, planning and authority application approval. This plan does not relate directly to the architectural design process. Also not related to the quality of production, or the quality of the system gauging the production. The two models are based on the initial academic knowledge an architect obtains when working on one project and in a team. They are not even connected to project management knowledge.

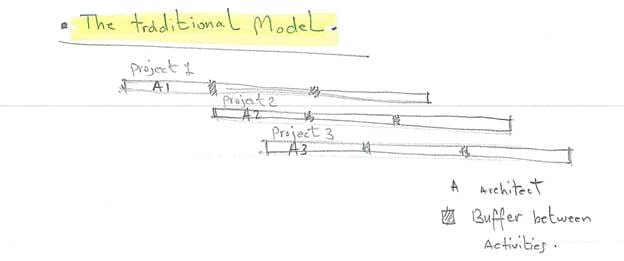

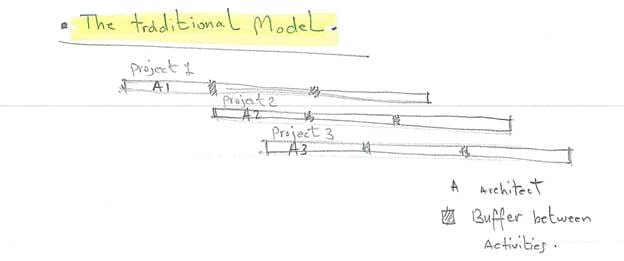

When an architect is performing the architecture design activity alone, he is responsible for the whole process. Starting from concept design and related tasks, design development, and coordination with other disciplines. In addition, the final detail design stage. This is called the traditional model, where the architect works alone on the project. If the firm has multiple projects, several architects will work on them. See Figure 1, the traditional model projects, architects A1-A2-A3, and a buffer in between the project phases.

I have discussed in the previous articles how the design manager identifies team members and their skills, and how they fit every task in a project. Adding to that, how the design manager shifts the team member from project to project. Based on the design management plan skills matrix, I will come to this later article. To complete another task on another project when required. So several architects and engineers will work on one project in different timelines of the architectural design process. Also, shift them to another project using the two techniques by the design manager indicated in my previous article. This is the sequential design model where several architects work on the project A1-A2-A3, and so on. As illustrated in Figure 2, the sequential model various architects work on the project.

Professional bodies identified several quality systems combined with the architectural design process. These systems vary in terms of work, process, and goals. For example, Total quality management (TQM), Lean Project management ( LPM), Prince 2 Project management (PRINCE 2). In addition, to Buffer management technique, Value management (VM), Six Sigma business management approach. Also, some firms use these systems in business, construction, and other in industry. All these systems target efficiency of work, reduction of defects, and increasing revenue.

I have discussed that architecture is different than manufacturing a Pepsi Cola product, or a Lincoln car. In all cases, this quality management seeks to produce quality products.

Firms and research created the total quality management system before the ISO quality management 7 principles. And now all firms must pass the quality management certification process of ISO. After that, bodies will allow the firm to operate in that country in the world. The ISO and this system do not differ from the architectural design process in the core areas. The tasks include defining customer needs, the team involved in the work, the process used, and the decision-making process. Also, how to improve the design process, management, and evaluation of total design quality.

Firms and researchers invented Lean project management for industrial work. Their goal was to eliminate waste in the manufacturing process. Such as waste created through overburden and waste created through unevenness in workloads.

PRINCE2 project management was created for the construction industry. This differs from the design quality procedures. In practice, it is not allied to the architectural design process.

Firms and factory owners adapted the Buffer management technique from the supply chain industry. To use it to mitigate the risk of loss of material, time, and revenue in Industrial work.

The value management system is a BS standard to be used with the existing management system. A system that focuses on how to measure value. What are the functional drivers and objectives to find solutions to increase innovation in business? It has four principles, including strengthening value orientation: applying functional thinking. Also, applying a structured holistic approach, and managing complexity, risk, and uncertainty.

Finally, Six Sigma quality management and lean project management include many similarities. But here the focus is on eliminating defects rather than waste. Its principles are to define a problem, measure performance, and analyze process. Also, improve process and control the new process to eliminate defects. Figure 3, shows the Six Sigma principles in business management. MBA holders rely on it in improving firms’ work in practice.

Firms use the six systems I have presented in parallel with the architectural design process in practice. As per the professional bodies, they group them into two groups. One group’s goal targets the increase of business and production quality. The second group goal targets the increase in project production quality.

The design management plan focuses on increasing the quality of the design process production, but not the construction activities. So these quality management systems serve the company system, but not the design management plan. In practice, I have worked as a design manager for several years. I have not applied or observed or worked with other design managers who have applied these quality management systems. firms rarely use these systems in the design management plan in practice.

The design management plan includes six activities in reality linked to the architectural design process. Surely, At the top of the design management sits the design manager. The first he identify the Client’s needs, project program, and requirements. Second, defining the goals and objectives of the project. Third, selecting the team and the stakeholders involved. Fourth, process, design models for use in the project. Fifth, systematic evaluation, assessment, and review of the project design quality produced. Sixth, submittal procedures of design and project documentation to the client and the authority.

The six activities in the design management plan use any design models I presented. They do not intersect with the former systems. The only similar work comes in the fifth activity. The systematic evaluation, assessment, and review of the project design quality. indeed, the work produced within the project architecture design phases.

None of these quality management systems a design manager can use in practice. He cannot use them to evaluate, assess, and review the project design and production. He can not use them for two reasons. Firms cannot separate this system because of the direct link to the business operations and production quality.

Now, how does the design manager in his design management plan evaluate, assess, and review the design production?

I will go through the criteria that a design manager uses to evaluate and assess quality. The ones he uses in the six activities of the architectural design process. And to answer this question, how much the architectural design achieved. You can identify by comparing the assessment criteria of every one of the six activities.

One- client needs

I present here many assessment criteria for the judgment of production. Clients seek innovative architectural design. Designs that fit the project construction budget. A design that fits the project program in terms, for example, no of specified residential types and units. A design that is not complex and easy to construct within the country’s available technology and construction methods. Designs that provide maximum revenue and have a half-life cycle longer than the normal equivalent in the market. And finally, a design that will not add extra cost in operations for maintenance and facility management.

Two- goals and objectives

This includes client satisfaction with the architecture design starting from the concept design. A concept design that fits the project location context. Producing an architecture design that balances innovation and practicality. Achieving sustainable architecture requirements. The satisfaction of the end user of the project function. A design that does not require heavy expertise to complete its phases. Designs that meet the international standards and local standards, and regulatory requirements. And a design that leads to another project award from the same client, or to be used as a project of achieving excellence in the firm’s marketing process.

Three- the architecture team and stakeholders

The team that will work on the project with high-level expertise and talented staff. Stakeholders who possess a high level of expertise in the field of architecture design. Team members who have worked on a similar project and produced the desired production and many other interpersonal skills.

Fourth- process and design models

If using the traditional model, how much support is needed, if required, that will not affect producing work at deadlines. Also, when using the sequential model, how many staff will work on the project? And if they are from other teams or permanently on the team, that will not affect producing work at deadlines. Is the cycle of doing architecture design followed as per plan among the team members? And how much time did the design management higher-level spend in the process?

Fifth- evaluation, assessment, and review of design production quality

Is the evaluation as per the code of standards? Is the assessment as per company standards? Does the concept design fit the project location context? Is the project exceeding industry standards of artwork? Did the concept design respond to the client’s needs and requirements? Is the architectural design achieving the planned goals and objectives? Is the presentation work realistic? Does design production follow the company procedures? Is the design compatible with the structural system? Is the design compatible with the MEP systems and the ease of design? Did the team take more time than the planned time to produce the work? Is the architecture design adaptable to changes in the future, if required, or a complex design? Are the design drawings of all disciplines coordinated and identical in terms of architecture and structural design?

Six- Client, authority submittals

Are the project submittal deadlines respected, or is there a delay? Are the project submittals matching the client’s deliverables requirements for every stage? Do the submittals follow the country’s rules and regulations? Are there any objections to the submittal, and how many times do the submittals have to be revised?

Firms rarely use QMS in practice, but only to develop the business system. The efficiency of the design models affects the quality of services provided. Indeed, this can be achieved by giving attention to many factors. These include uniform standards for individual projects, a consistent approach to client relations. In addition, a uniform quality review process and clear roles of staff. High-quality work means a highly efficient system.

Design models in design management and a well-designed and easy-to-use quality assurance system are used as an underlying framework for all the firm’s activities. Such a system provides the firm with a clear management structure understood by the firm’s staff. A policy and procedure to enable the delivery of the services promised to clients. A training policy for all firm staff and an inclusive risk management system. In my previous experience, I have not witnessed other design models in design management other than the ones I have shown here. These design models are used uniformly by all types of firms, local or international, as I witnessed in my career. The big challenge firms face in practice is how to combine these models with QMSs. Also, other related articles you can find in these links 1,2,3,4,5,6,7,8,9,10,11

[…] In the following graph, which is used to match staff skills, the firm’s design staff are categorized and grouped based on the three divisions. The above right side of the graph, written in blue, is the skills related to managers and lead architects. The following are the skills related to senior architects and architects. The above-left side shows the skills related to technicians. The graph has three arms that connect in the middle, and every end is the mark of the gauge for low skill. Every arm is related to the three major categories: management, design, and technician work. See Figure 1, the mapping staff skills and experience graph. This leads to building a skills matrix for a firm. Also, other related articles you can find in these links 1,2,3,4,5,6,7,8,9,10,11,12 […]

[…] Also, other related articles you can find in these links 1,2,3,4,5,6,7,8,9,10,11,12,13,14,15 […]

[…] Also, other related articles you can find in these links 1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16 […]

[…] architects team. Effective meeting procedures and eliminating wasteful habits. Also, specify what design models to use in the […]